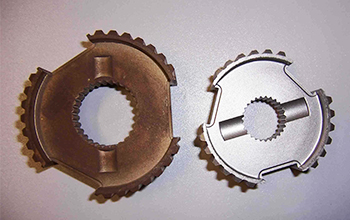

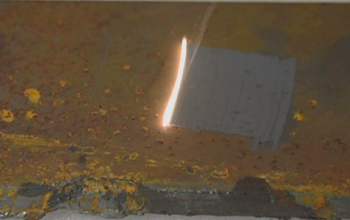

Laser cleaning technology refers to the use of high-power density laser beams to irradiate the surface of the workpiece, so that the dirt, rust or coating on the surface can be evaporated or peeled off instantly, so as to achieve the cleaning process. The laser rust remover is a new representative surface treatment of high-tech products, which is easy to install, operate and realize automation. This is easy to operate, and no chemical reagents, media, dust, or water is needed to connected to the power source cleaning. It can remove resin, paint, oil, stains, dirt, rust, coating, plating and oxidation on the surface of the object.

For more details about fiber laser cleaner, please send an email.

| Model | SF500HC | SF1000HC |

| Laser power(w) | 500 | 1000 |

| Laser Wavelength (nm) | 1064 | 1064 |

| Max Pulse Energy (mJ) | 50 | 50 |

| Weight of Cleaning Gun (kg) | 1.47 | 1.47 |

| Length of Cleaning Gun Line (m) | 10 | 10 |

| Net Weight of Machine (kg) | 215 | 220 |

| Overall Dimensions (L*W*H, mm) | 1010*745*1200 | 1010*745*1200 |

| Type of Cooling | Water-cooled | Water-cooled |

| Languages | 11 kinds of languages like Chinese, English, French | |

High cleaning efficiency and good effect

Automatic operation, stable cleaning, high efficiency, no need chemical cleaning liquid, no consumables

Real- time Monitoring

Cleaning specific positions and sizes

Maintenance-free

Stable laser cleaning system, low operating cost, almost no maintenance

Host Machine Control System

Clear and simple interface page

Various parameters can be set by yourself

Self-developed Spiral Cleaning Mode

Scanning length and width customized

Avoid the zebra crossing

Uniform cleaning interface

No damage to the substrate

The cleaning interface is uniform, no damage to the substrate.

Adapt to Different Brand of Laser Source

Greatly improving the scope of application of the system

| Cleaning methods | Laser cleaning | Chemical cleaning | Mechanical polishing | Dry ice cleaning | Ultrasonic cleaning |

| Principle | Laser cleaning | Chemical cleaning | Machinery/sandpaper | Dry ice | Detergent |

| Workpiece damage | slight | Damage | Damage | NO | NO |

| Cleaning efficiency | High | Low | Low | Medium | Medium |

| Safety/Environmental Protection | No pollution | Polluted environment | Polluted environment | No pollution | No pollution |

| Manual operation | Easy to operate | Complex operation | Complex operation | Easy to operate | Easy to operate |

| Cost | Low maintenance cost | High cost of consumables | Low cost of consumables | High cost of consumables | Medium cost of consumables |

Copyright © 2023Jinan Senfeng Laser Technology Co., Ltd. All Rights Reserved