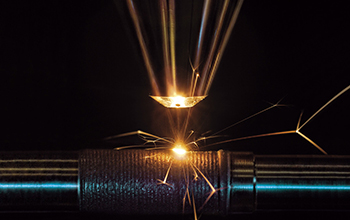

SFHS3050 high-speed laser cladding machine is a high-speed rotating cladding machine with a circular spot. This machine uses high-energy laser beams as the heat source to cladding powder materials on the surface of parts to prepare high-performance protective coatings, thereby improving the surface hardness, wear resistance, corrosion resistance, oxidation resistance, high temperature resistance and other properties of the material.

For more details or price of metal additive machine, just send e-mail to us.

| Model | SFHS3050 | SFHS6050 |

| Laser Power | 6/12kW | 6/12kW |

| Power Feeder | SENFENG dual-cylinder pneumatic powder feeder | SENFENG dual-cylinder pneumatic powder feeder |

| Laser Cladding Head | SENFENG high-speed laser cladding head | SENFENG high-speed laser cladding head |

| Control System | SENFENG intelligent cladding system | SENFENG intelligent cladding system |

| Max Load of Table | 2T | 2T |

| Max Length of Workpiece | 3000mm | 6000mm |

| Max Clamping Diameter of Workpiece | Φ800mm | Φ800mm |

| Max Swing of Workpiece | Φ800mm | Φ800mm |

| Chuck | Φ500mm (self-centering, three jaws) | Φ500 (self-centering, three jaws) |

The coating is metallurgically bonded with the substrate, with high bonding strength and good spalling resistance.

Good selectivity, which can strengthen and repair different parts of the workpiece.

High powder utilization rate, deposition close to the final profile, small processing capacity.

Small heat input and deformation,low pollution and environment friendly

| Laser cladding | Spraying | Galvanizing | Overlaying welding | |

| Coating layer thickness | 0.1-10mm | 0.1-5mm | 0.1-100μm | 0.1-several mm |

| Workpiece deformation | Small | Small | Small | Big |

| Bonding form with substrate | Metallurgical bonding | Metallurgical bonding | Mechanical bonding | Metallurgical bonding |

| Bonding strength | High | Relatively low | Low | High |

| Coating layer hardness | Controllable | Controllable | High | Controllable |

Metal additive machine is mainly suitable for surface modification of materials, surface repair of products and prototype manufacturing. It is widely used in coal, metallurgy, offshore platform, papermaking, domestic household appliances, automobile, ship, petroleum and other industries.

Copyright © 2023Jinan Senfeng Laser Technology Co., Ltd. All Rights Reserved