Views: 1928 Author: Rebecca Publish Time: 2021-08-03 Origin: Site

10kw and above laser cutting machine has become the new trend in metal processing industry. Obviously you don’t buy it as a show-off, the ultimate goal for you to upgrade your equipment to this high level is because it helps you save money, which is to say, helps you gain more profit. In this article, I would like to show you by statistics and examples how 10kw+ laser cutting machine can help you make money and how much you can earn by making this purchase.

1. The comprehensive cost drops dramatically

This is the most apparent way to show the money that you can save. When it comes to cost, we are basically talking about the cost of gas, electricity usage caused by the laser cutting machine and the air compressor. You can see clearly from the below chart that compared with a 6kw machine, the cost of a 12kw drops around 50%. Among these, the cost saving for cutting stainless steel stands out, which is 55%-75% when using Nitrogen and 72%-85% with air. If you don’t have a high bar on the edge quality, cutting with air for stainless steel saves the most. With real numbers provided, it’s quite shocking when you see how much we can save, and we are just getting started.

Cost comparison between 6kw and 12kw | |||

Material | Thickness | Gas | Cost Decreasing Rate |

Carbon Steel | 6-14mm | 6kw: Oxygen | 43%-63% |

12kw: Nitrogen | |||

16-25mm | Oxygen | 25%-40% | |

Stainless Steel | 6-16mm | Nitrogen | 55%-75% |

Air | 72%-85% | ||

Aluminum | 6-14mm | Air | 43%-55% |

2. Efficiency increases significantly

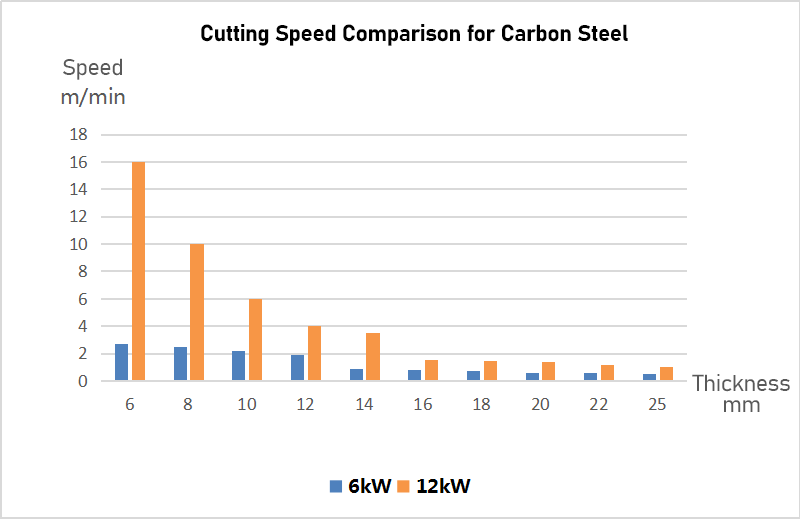

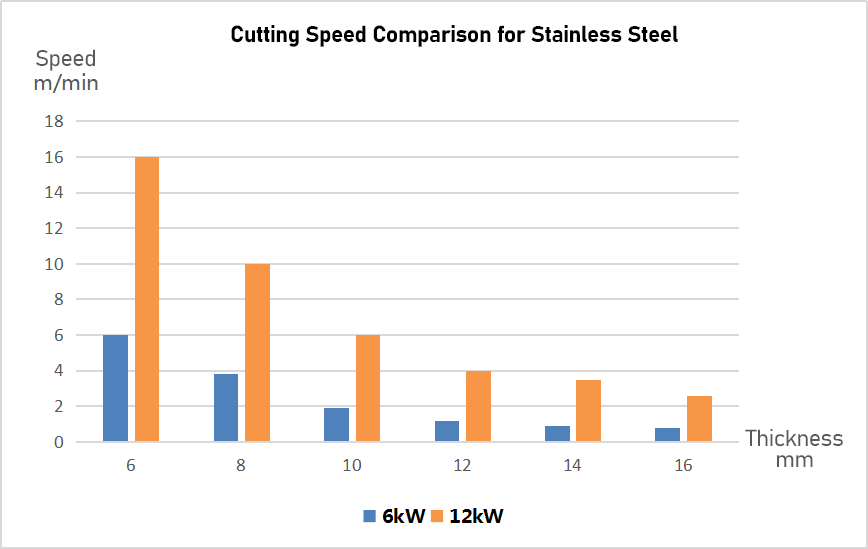

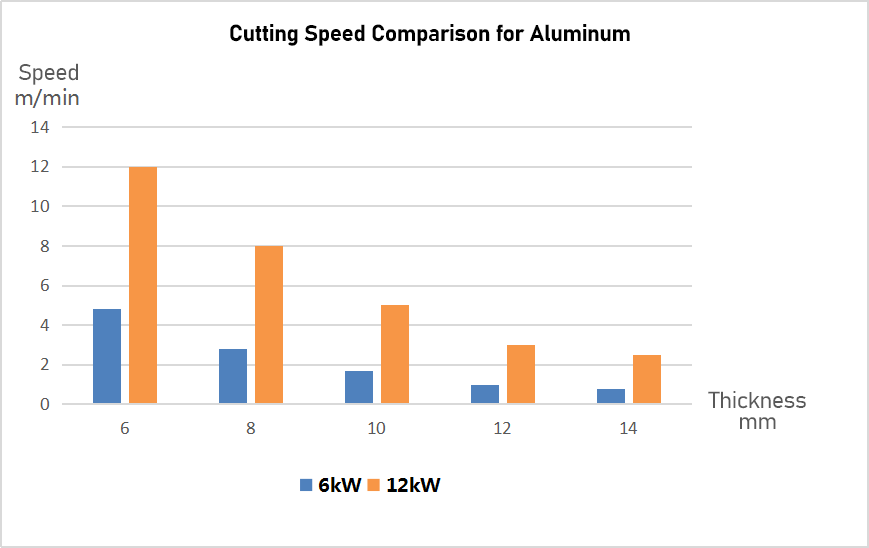

The cutting speed increased a lot when you operate with a 12kW laser cutter, which directly leads to the improvement of efficiency. In modern production, it’s not an overstatement to say that efficiency is money. By increasing efficiency, you can produce the same amount of workpiece within much less time, and that’s a great saving on gas, electricity and labor! What you save is what you gain, right? Check the below charts to see the details of the material you are dealing with and here I am using 10mm carbon steel as an example: the speed for a 12kW is 3 times faster than 6kW, which means you can finish your ANNUAL production in FOUR months! That’s quite convincing and appealing, right?

3. Excellent ROI

When you want to make a purchase of a new machine or equipment, ROI should be the top thing that you would consider. Let’s do a real math here: say if the factory works two shifts with each shift of 8 hours, and 26 days a month, cutting the material of 6mm stainless steel with a 20kW machine. Profit per meter for 6mmSS is 3 RMB (this varies from different market) and the cutting speed with a 20kW is 18.4m/min(this has deduct the time we spent on adjusting, loading and uploading, etc.), then, we can get the monthly profit here:

3RMB*18.4m/min*60mins*8hours*2shifts*26days=1,377,792RMB

I need to say no more, the numbers speak for themselves. Also you can calculate your own monthly profit using the below formula:

Gross profit(USD/m)*cutting speed(m/min)*monthly working time(min)

4. Fine and delicate cutting quality

As an integrated entrepreneur, you must think of quality as the lifeblood of your production. With 10 kw and above laser cutter adopted, you can literally say bye-bye to burrs and say hello to the smooth edges. This greatly increase the pass rate of the workpieces, which significantly saves the raw material, as well as labor, time, gas, electricity and so on. Also, no subsequent grinding is needed, so you don’t have to invest more on another machine or equipment or hire more workforce. Below is the sample comparison to show 10kW and above ensures higher accuracy and smaller taper ratio of the cutting surface.

5. Great potential in expanding you business

10kw and above can realize thick material cutting up to 30 mm for carbon steel and 22mm for stainless steel, and this is not the maximum cutting thickness but the thickness it can process for mass production. And also, we have different sizes for the working table to choose and you should know a 10kw+ laser machine works better with larger working tables. All these can enable you to have the capability to process thicker and larger raw materials. You might say, I don’t need to cut with material this thick or large, but the truth is that you can never be too prepared when new opportunities come, especially in this fast-changing industry. And an equipment with 10kw will show the company strength to your partner, which makes the cooperation more smoothly.

6. Optimum choice of all

For our 10kw and above cutting machines, we have equipped them with the optimum configuration that we can think of to make sure it can work properly with such high power laser. You must know how much heat it can create with 10kw and what that heat can do damage to the machine bed. Well, we have made several improvements to avoid the deformation, such as the application of graphite, which is a great heat-resistant composites, and also the use of red copper, which is highly reflective to resist the damage from high-power lasers. Apart from the heat, high power machines also create quite some smoke, and that’s all been taken care of by our technology of partition dust removal system. I don’t need to say more, you can view the video here to see how effective this function is.

With all these being said, you are pretty sure that you are considering one of the best options for your production line, and I can assure that you don’t need to upgrade your equipment in the near future with its superior performance and durable working time. It’s not a purchase but a worthwhile investment. Seize the trend with 10kW+ laser cutter! Talk to our professional consultant and get yourself a industry-leading laser cutting machine to exceed your competitors.

Whatsapp: 86-13210546543

E-mail: senfeng@sfcnclaser.com

Copyright © 2023Jinan Senfeng Laser Technology Co., Ltd. All Rights Reserved