Views: 801 Author: Summmer Publish Time: 2022-05-02 Origin: Site

With the popularity of fiber laser cutter, the competition in the laser processing industry has become increasingly fierce. How to improve efficiency and reduce costs has become the concern of most customers. Today, taking 6kW fiber laser cutter and 12kW fiber laser cutter as examples, we analyze which fiber laser cutter is more cost-effective in terms of processing cost, processing efficiency and processing effect.

1.Processing Cost Analysis

In the cost analysis, the comparison is mainly made from three aspects: the electricity cost of the fiber laser cutting machine, the electricity cost of the air compressor and the cost of the auxiliary gas. From the electricity bill of the fiber laser cutting machine, the total power consumption of the 6kW fiber laser cutting machine is 38kW/h, while the total power consumption of the 12kW fiber laser cutting machine is 68kw/h. From this aspect alone, the cost of a 12kW fiber laser cutting machine is higher than that of a 6kw fiber laser cutting machine. Judging from the electricity cost of the air compressor, both use 3Mpa air compressors, and the total power consumption is 15kW/h, and the cost of both is the same. Finally, from the perspective of the cost of auxiliary gas, three materials of carbon steel, stainless steel and aluminum are used for cutting test. The specific situation is shown in the following figure:

Cost comparison between 6kW and 12kW | |||

Material | Thickness | Gas | Cost Decreasing Rate |

Carbon Steel | 6-14mm | 6kW: Oxygen | 43%-63% |

12kW: Nitrogen | |||

16-25mm | Oxygen | 25%-40% | |

Stainless Steel | 6-16mm | Nitrogen | 55%-75% |

Air | 72%-85% | ||

Aluminum | 6-14mm | Air | 43%-55% |

From the above data, it can be seen that compared with the processing cost of 6kW fiber laser cutting machine, the cost of 12kW fiber laser cutting machine can basically be reduced by more than half, among which stainless steel has the greatest advantage, followed by carbon steel and aluminum. Air is used as an auxiliary gas when cutting stainless steel, and the unit price processing cost is the lowest, which can meet the products that do not require high cutting sections.

2. Processing Efficiency

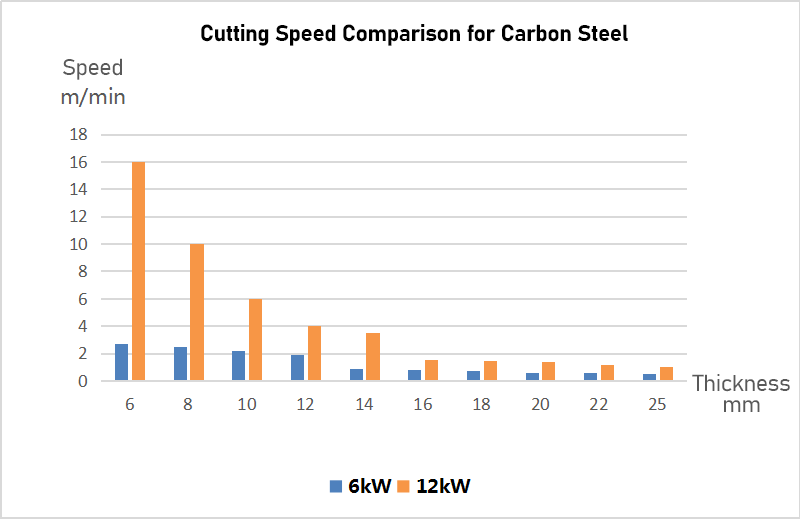

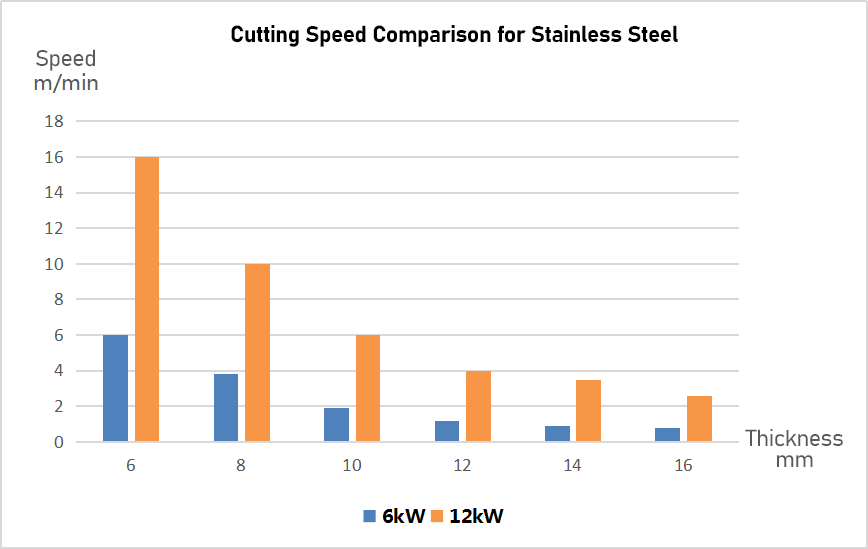

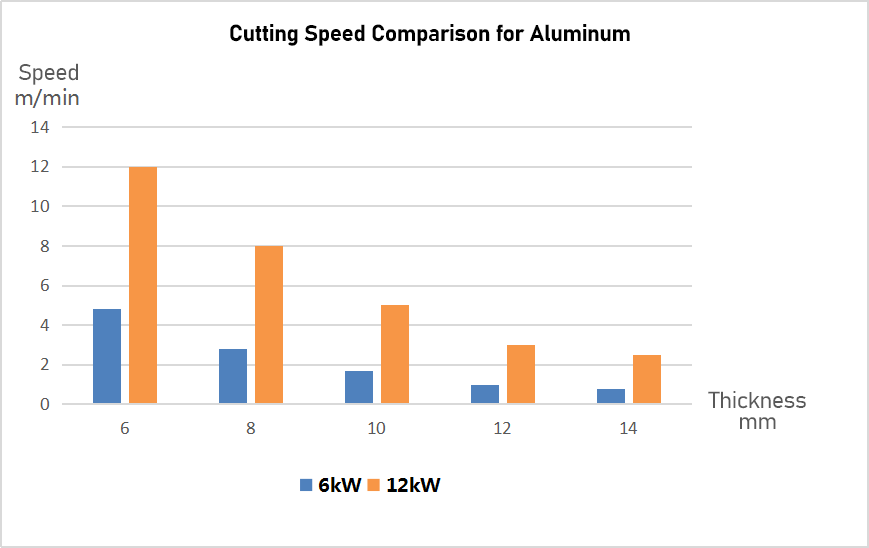

When comparing the cutting efficiency, we mainly compared the cutting speeds of 6kW and 12kW fiber laser cutters for cutting carbon steel, stainless steel and aluminum. The result is shown in the following figure

From the tested cutting speed, it can be concluded that when cutting carbon steel, the speed of the 12kW fiber laser cutter is 87%-493% faster than that of the 6kW laser cutting machine; when cutting stainless steel, the speed of the 12kW laser cutting machine is faster than that of the 6kW laser cutting machine. The cutting speed is 163%-289% faster; when cutting aluminum, the speed of the 12kW laser cutting machine is 150%-213% faster than that of the 6kW laser cutting machine.

3. Processing Effect

From the processing effect, the 6kW fiber laser cutting machine produces more slag when cutting 16mm and 20mm stainless steel, while the 12kW fiber laser cutting machine has almost no slag when cutting stainless steel of the same specification. At the same time, when cutting 16mm and 20mm carbon steel, the 6kw laser cutting machine can only cut out a matte surface with a large taper; while the 12kW fiber laser cutter can cut out a smooth and bright surface with a small taper. As shown below:

In terms of overall economic benefits, the price of a 12kW fiber laser cutter is 30%-40% higher than that of a 6kW fiber laser cutting equipment, but the production efficiency is several times higher than that of a 6kW fiber laser cutting equipment. The processing cost of 12kW fiber laser cutter is also more than half lower than that of 6kW laser cutting equipment. This greatly reduces the processing time and processing cost of a single workpiece, and the processing effect is better, which can create a value multiplication effect for customers. Of course, customers should also purchase suitable processing equipment and choose suitable processing methods according to their actual needs. If you want to learn more about 12kW fiber laser cutter, please contact SENFENG.

E-mail:senfeng@sfcnclaser.com

Whatsapp:+86-13210546543

Copyright © 2023Jinan Senfeng Laser Technology Co., Ltd. All Rights Reserved