Dear customers from Germany and other European countries:With the rapid development of global manufacturing, LEIPZIG INTEC has become one of the most important fairs in the industry. The event will take place from Mar. 11 to 14, 2025, in Leipzig, Germany, taking on cutting-edge industrial technologi

Dear customers in and around the Europe, The MECSPE 2025 will be held from Mar. 5 to 7 at the BolognaFiere Exhibition Center, Bologna, Italy. Focused on mechanical manufacturing, metalworking and laser technology, this event has attracted professionals and companies from around the world over the ye

In the first half of 2024, we will showcase nearly 30 types of fiber laser machines in 20+ countries. SENFENG is eager to cooperate and communicate with merchants in need of sheet metal working, no matter what country or industry they come from. And we're looking forward to finding out what's new in the industry with all of you.

The second half of 2024 has come. We will travel through the Asia, America, Europe and Central and East Africa to present our laser machines, automation and new energy to local and nearby customers. Here is our specific schedule. Mark your calendar to visit these exhibitions on time. Be there or be

It is well known that CNC press brakes are widely used in metal processing field, and their high precision and high efficiency are deeply favored by manufacturing companies. However, for novice operators, mastering some operating skills is a key challenge. The following are 10 practical tips that no

Peru Latin America SENFENG LASER InvitationExpo Perú Industrial 2024 To all our regular and new customers:We hereby invite you to visit the only industrial exhibition in Peru. You will touch cutting

Selecting a CNC press brake is a critical decision that can greatly influence your production efficiency, product quality and overall profitability. With a myriad of options available in the market, it is essential to evaluate several factors below before making your choice. Here are 10 factors to g

Laser cutting machines are essential tools in various industries, such as metal fabrication and automotive manufacturing. However, their prices may vary greatly because of several factors. If you're in the market for a laser cutting machine, knowing factors below will help you make a more informed d

Exhibition Name: Expo Perú Industrial 2024Time: Aug. 22-24, 2024Add: Jockey Exhibition Center, Lima, PeruSENFENG Booth: A1

If you are interested in the exhibition or in SENFENG, you may contact our overseas sales engineers ahead of time. They will provide you with assistance in terms of exhibition address, routes, transportation and more. In addition to the real machine above, we will also prepare various paper publicity materials for visitors to increase your understanding of SENFENG.

Laser tube cutting machines have developed into a sharp weapon to address many challenges difficult for traditional metal processing. Their performance in precision, waste, cutting speed and design flexibility makes them an essential tool in modern manufacturing industry.

Laser tube cutting machines have revolutionized manufacturing and fabrication industries by providing precise, efficient and versatile cutting solutions for various types of tubes and profiles. As more companies recognize the benefits of laser cutting technology, the demands for these machines has s

Laser sheet metal cutting machines have revolutionized the manufacturing industry, particularly in the cutting of sheet metals. Their precision, speed and versatility make them indispensable in various sectors, from automotive production to aerospace. This article will delve into their main configur

When it comes to modern manufacturing, fiber laser cutting technology is replacing traditional processing methods and becoming an essential helper for various industries to improve work efficiency and product quality. In plate processing field, the laser sheet metal cutting machine with its excellen

Sheet metal laser cutting machines have revolutionized the manufacturing and fabrication industry. These machines provide high precision, fast speed and versatility, making them essential for various applications from automotive to aerospace. However, for beginners, operating a sheet metal laser cut

SENFENG may also tailor to all customers in terms of laser power, working area and specific configuration, so as to further upgrade metalworking in all walks of life.

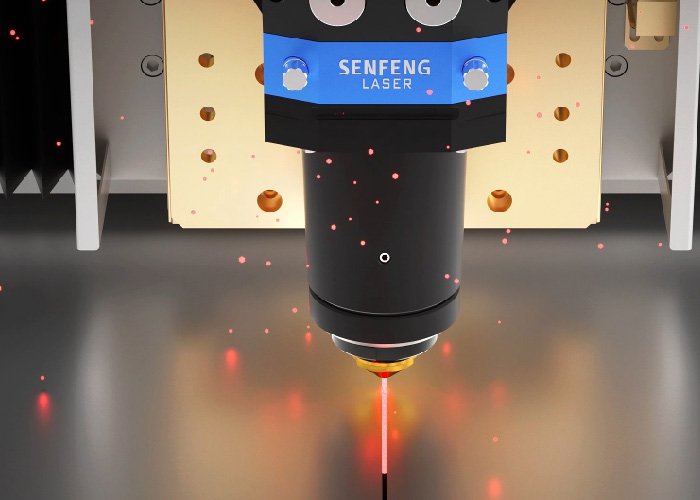

SENFENG has been deeply cultivating laser technology for nearly 20 years, incl. integrate automation technology, lay out laser intelligent manufacturing and carry out a full industry chain development model that takes into account of laser cutting/welding/automation/new energy.

As for laser cutting, power rating of laser is regarded as a pivotal factor in assessing the machine's performance and efficiency. Laser cutting machines are commonly available in power ratings of 3kW, 4kW, 6kW, and even higher, such as 80kW in the case of SENFENG, each tailored to specific operatio

The 66th International Technical Fair 2024 will be held in Belgrade Exhibition Center, Serbia from May 21 to 24, 2024. SENFENG hereby invites all of you to come to the fair site to appreciate the great achievements of international industry. Welcome to stop by SENFENG booth: Hall 1, 1125.

The 6kW fiber laser cutter stands out as a game-changer in the realm of metal fabrication. With its exceptional power and precision, it offers unmatched capabilities when it comes to cutting metal sheets, establishing itself as an indispensable tool across a multitude of industries.